Stainless Steel Investment Casting :

Where Precision Meets StrengthDo you remember how our elders used to say, make good choices, make ideal choices. Don’t worry we are not here to discuss philosophy but we just want to get you in the rhythm for what is about to come next.

What if we told you the same law of ideal choices applies to a metal (IN PROCESS OF STAINLESS STEEL INVESTMENT CASTING) that is also a beacon of strength and exceptional corrosion resistance. Yes, we are talking about Stainless Steel Investment Casting and what makes it an ideal choice for castings that serve a variety of industries, like automotive, aerospace, marine, medical, and food processing.

Precision Process of Stainless Steel Investment Casting

Due to the stainless steel’s ability to be created into complex metal parts in a wide range of shapes and sizes, the Stainless Steel Investment Casting process is also called precision casting.

We begin the metal forming process of investment casting in stainless steel with the wax pattern creation, then it is surrounded by a ceramic shell to form a mold. The next step starts by melting out the wax, leaving just the ceramic shell as the mold.

And finally, stainless steel in its molten form is poured inside the mold, giving you the casting component. If you happen to have casted some sought of complex part machining process maybe required after cooling of the metal.

What makes stainless steel so special?

Frankly, stainless steel is like tony stark, the famous Iron Man, smart, & intelligent. But just like IronMan needs a suit to fly, stainless steel needs to be mixed with other material to help him realize its true strength & potential.

While the process of stainless steel takes place, at least 10% chromium is added which forms a chromium-oxide film. This layer gives stainless steel the ability to heal in presence of oxygen blessing it with corrosion -resistant properties.

Exploring the super powers of stainless steel, with benefits of stainless steel investment casting

Known for making high-precision parts with the best surface finish, stainless steel investment casting is the best choice for things that require precision and aesthetics, like Aerospace, Automotive, Medical, & etc,.

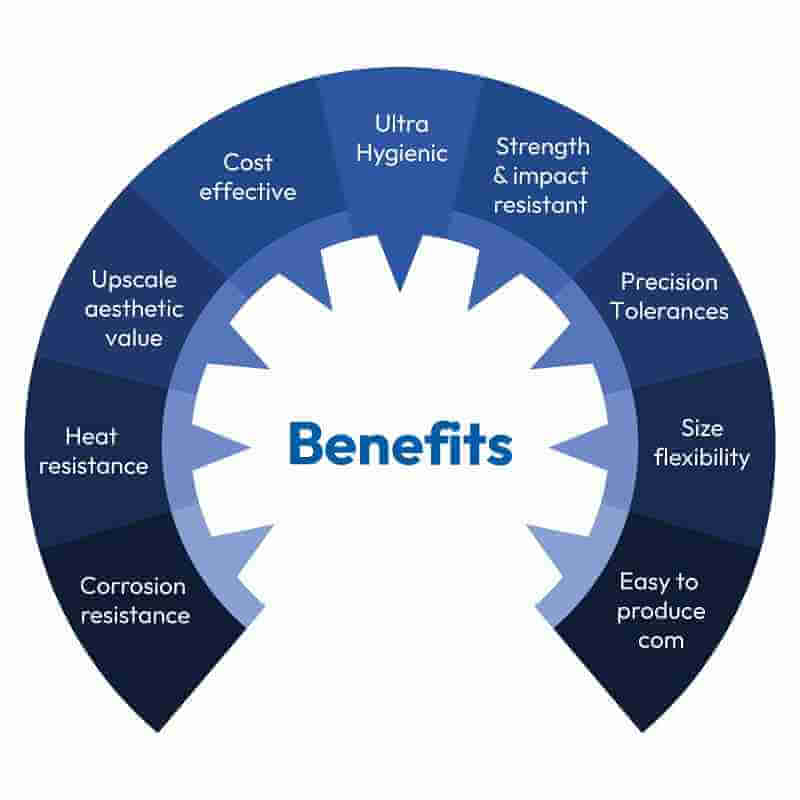

The benefits

Corrosion resistance

Heat resistance

Upscale aesthetic value

Cost effective

Ultra Hygienic

Strength & impact resistant

Precision Tolerances

Size flexibility

Easy to produce complicated shapes

Classification of Stainless Steel

Based on their crystalline structure stainless steel is classified into 5 major types, based on your requirement and need, the stainless steel investment casting can use a variety of alloys giving every category of stainless steel different properties.

Austenitic :

Strong, ductile, and high heat resistance. It is the most commonly used stainless steel.

Martensitic :

Often used where stainless steel is required to show high tensile strength & intense impact resistance.

Ferritic :

Due to its over 12% chromium and very low carbon content it is not hardenable by heat making it an ideal choice for welding treatments.

Duplex :

With both the ferritic and austenitic alloys characteristics present, duplex stainless steel is used for products that have more environmental exposure.

PH (Precipitation Hardening) :

The most dependable and toughest stainless steel comes from the PH family. They are used for parts and products that are not supposed to be bent.

Stainless Steel Investment Casting & its Popular Grades

Depending on the applicability, quality, & other various properties, we at Sumangal Casting, cast various grades of stainless steel alloys depending on the client’s requirement. Thus, here are some most popularly used stainless steel alloys.

| Alloy | Usage | Industry |

|---|---|---|

| 304 | Mostly used in the food industry due to its cleanliness & corrosion resistance properties. | Medical, Food,Mining, Housing,Petrochemical |

| 316 | The alloy with the superior corrosion resistance,it is so apt that it is most commonly used in marine industry. | Food & Dairy,Maritime,Chemical,Medical, Gear |

| 410/416 | This grade would rather break than bend under pressure making it very high strength & machinable. | Automotive,Housing, Machine tools |

| 17-4 | Considered the toughest in the stainless steel family. 17-4 is used for parts that are not supposed and should never bend. | Military,Aerospace,Machine tools,Medical, oil & gas |

Sumangal Castings Pvt. Ltd. - Your best choice for stainless steel Investment Casting

Let’s just say, stainless steel casted at Sumangal’s stainless steel investment casting facility is being supplied to the U.K, US, and many other countries. This shows our ability to do stainless steel investment casting of best and high quality with cost effectiveness at the center.

Moreover, our manufacturing facilities are well equipped with the latest technology and our R&D department houses the brightest minds that are continuously innovating.

Furthermore, with a legacy built with trust and courage we have been delivering the best to the casting industry for over 40 years and have 30 years of expertise in stainless steel investment casting.

So, you have reached this far already. Well, then we know exactly what you want. And, rest assured we definitely have it.