What is Investment Casting?

Investment casting, also known as the lost wax process, is a precise manufacturing technique. It starts by coating a wax pattern with a ceramic shell. Once the ceramic hardens, the wax is melted out, leaving a hollow mold. Molten metal is then poured into the mold, taking the shape of the original wax pattern.

After the metal cools, the ceramic shell is removed, revealing a highly accurate metal component.

Investment casting uses ceramic molds to create smooth and precise metal parts. It's especially useful for specialized needs like Stainless Steel Investment Casting, where strength and accuracy are essential.

Why is Investment Casting the Preferred Manufacturing Process?

By blending artistry with precision, investment casting delivers complex, high-quality metal components for a wide range of applications.

Developed over 5,500 years ago the ancient amalgamation of art and science, ‘investment casting’ traces its root back to both Egyptian & Chinese civilizations.

The Investment Casting Process: Step-by-Step

Gears, cams, turbine blades, ratchets, machinery components to parts of complex geometry most of the things that we see or use around us are made using the process of investment casting.

So let us understand the intricate process of investment casting point by point.

Investment Casting Design Review & Pattern Fabrication

We start by reviewing the design for manufacturing with our customers including evaluation of print dimensions marking the start of the very intricate manufacturing process.

Moving ahead, fabrication of intricate patterns takes place using wax or similar materials. It provides us a clear picture for post-case material requirements, and gate placements. This process of investment casting helps us in determining precise duplication and expected tolerances for fit, form, and function of the final product required.

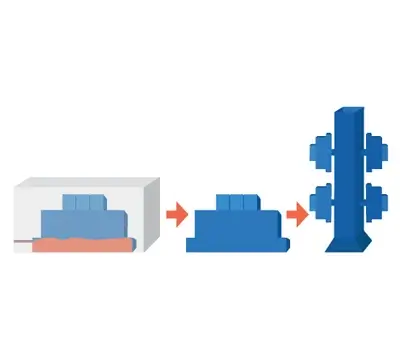

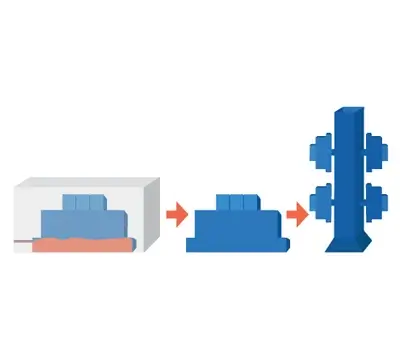

Investment Casting Mold Preparation & Design Building

This process starts with a carefully crafted wax injection mold that forms wax patterns replicating the final part. Our team at Sumangal Castings Pvt. Ltd collaborates with the mold builder to design and create these molds right here at our investment casting foundry. Built for durability, these molds are designed to produce millions of wax patterns throughout their lifespan.

Investment Casting Wax Pattern Creation

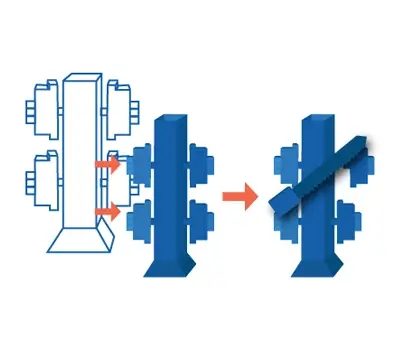

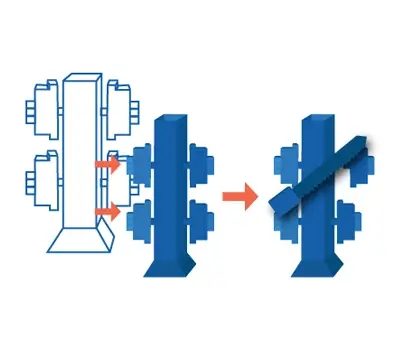

Once the wax injection mold is prepared for production and sent to the Wax Room for pattern creation. Anywhere between one and 100 wax patterns are injected and attached to a pre-made wax runner system, called a “tree.” This tree, or cluster of wax parts, is then sent to the Dip Room for the next step in the process of investment casting.

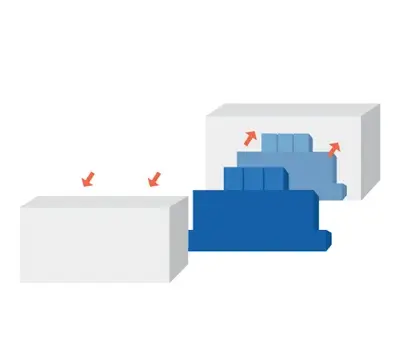

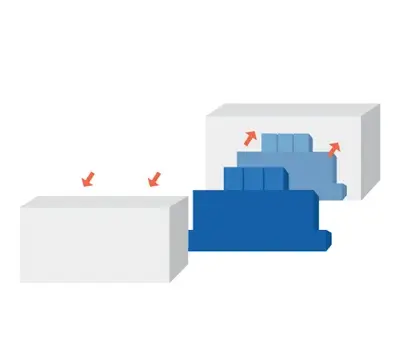

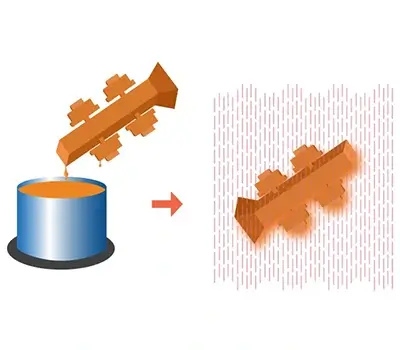

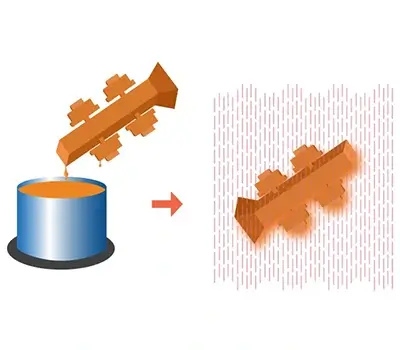

Investment Casting Ceramic Mold Construction

During this process of investment casting the wax tree is dipped into ceramic slurry, and then coated with sand to form the first shell layer. This dip-and-coat process is repeated 6 to 8 times, with drying periods in between, creating a strong, laminated ceramic shell.

This step ensures the creation of strong molds, ideal for processes like Stainless Steel Investment Casting, which demand high precision.

Afterward, the shell is dried for 24 to 36 hours before the wax is removed, leaving a durable mold for casting.

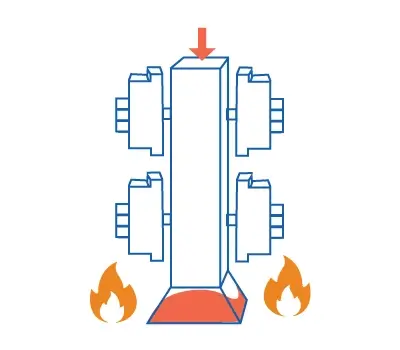

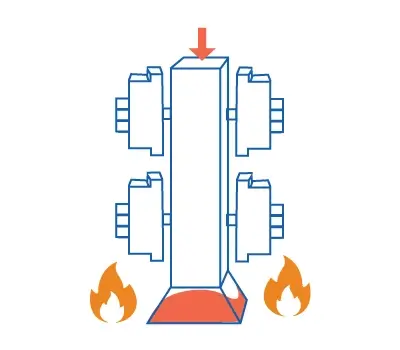

Investment Casting De-waxing (Lost Wax Process)

The wax-coated ceramic shell is placed in an autoclave, where high pressure and steam heat quickly melting the wax, leaving an empty ceramic mold. Once the wax is removed, the ceramic shell is transferred to the foundry to begin the investment casting process.

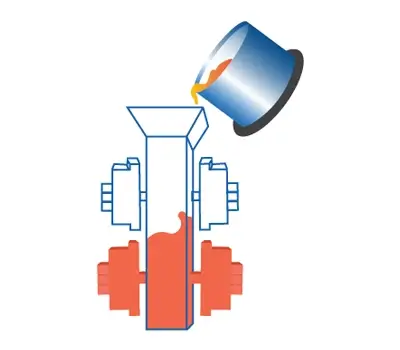

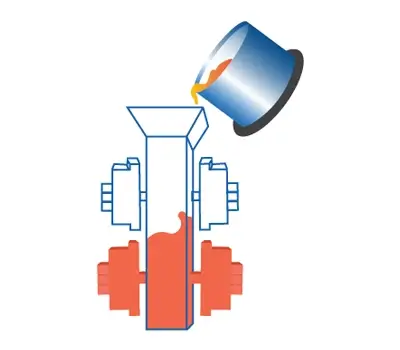

Investment Casting Metal Pouring at the Foundry

In this process of investment casting the ceramic mold is heated using a high-temperature oven at around 1000°C (1832°F) to harden and prepare it for the metal. The mold is taken out of the oven after being cured and molten metal is quickly poured into it, filling every part of the cavity to form the final shape.

Investment Casting Shell Removal & Part Extraction

This is the final step of investment casting in terms of manufacturing . The metal has cooled off and the brittle ceramic shell is broken away using water jets, vibration, or similar methods. After the ceramic is removed, the metal parts are separated from the gating system by cutting with saw, vibrations, or liquid nitrogen.

Investing Casting Final Finishing, Inspection, & Delivery

Once the additional surface finishing processes like polishing, grinding, & heat treatments as per the client’s requirements are done our teams of highly qualified individuals perform quality inspection, keeping the precise and accurate standards throughout the process of investment casting.

Finally, manufactured goods are delivered to you with utmost care.

Industries That Rely on Investment Casting

Aerospace

Aerospace

Pumps & valves

Pumps & valves

Automotive

Automotive

Agriculture

Agriculture

Maritime industry

Maritime industry

Key Benefits of Investment Casting

Investment casting uses ceramic molds for the casting process which in return gives excellent surface and smooth finish.

The amount of machining required after casting is shortened due to tight dimensional tolerances. Moreover, it provides a smoother surface (125 RMS).

Due to its versatile nature multiple metal alloys such as bronze, stainless steel, aluminum, etc. can be used in investment casting.

Investment casting is highly accurate, and repeatable designs can be used leading to minimal wastage as this process is lined to cast large metal varieties. Whether it’s intricate, small components or large pieces, the process remains straightforward and efficient.

Our Investment Casting Products

With quality, precision, and innovation take a look at our diverse range of investment casting.

Why Choose Sumangal Castings for Investment Casting?

As the state- of- the- art investment casting manufacturers Sumangal Castings Pvt. Ltd. not only provide advanced manufacturing, but we also go to lengths to deliver you the best with the help of our other integrated facilities.

-

Every product at Sumangal Castings is forged with quality and craftsmanship. Our team of highly skilled professionals tirelessly works towards optimizing processes that allows us to provide top of the quality products using diverse solutions to multiple industries.

-

Since high performance products are engineered with our industrial level processing facilities. We are able to meet the industrial standards for precision alloying to advanced heat treatments in our products. Our team of experts optimizes microstructures and provides a vast range of finishes. Sumangal Castings is not just suppliers; we are your partners for unmatched strength, durability, and corrosion resistance.

-

At Sumangal Castings, we don’t just meet industry standards; we go above and beyond. Our rigorous testing protocols are tailored to ensure our clients’ requirements every time.

-

Our state-of-the-art assembly facilities transform individual steel components into complex, functional structures and machinery. With the help of advanced robotics, precision tools, and a skilled team, we ensure that every part fits together seamlessly for flawless integration.

Investment Casting with Us – A Smart Business Decision

At Sumangal Castings Pvt. Ltd, we develop only high performing metal casts at our Pan-India investment casting foundry in Rajkot, Gujarat.

Using advanced manufacturing processes for producing high precision metal parts from a wide range of super & standard alloy materials at our foundry, we roll out dimensionally accurate and high-end metal products that adhere to the highest industry standards, making us the best investment casting manufacturer in India.

Although the investment casting process is done by ‘N’ number of companies, our advanced manufacturing plant allows us to make the difficult-to-process machine parts and materials with complex geometry in a very economical way.

Furthermore, we provide thorough consultation right from idea germination to rock solid implementation while maintaining quality, reliability, and certainty, making us the leading investment casting manufacturer in India, serving national as well as international clients.

Investment Casting Made Better with Us!

Standing the test of time investment casting is the perfect blend of art & science. Today, investment casting is used to produce high-quality metal components that meet the demands of diverse industries. And as we move forward, it remains an essential part of our journey toward innovation and excellence, shaping the world around us with every cast.

As the leading manufacturers and suppliers of investment casting, title bestowed upon us by our loyal customers. We at Sumangal Castings are making our mark in the market with not just national but international clients as well.

Using highly advanced technology and skilled professionals we are able to hit touchdowns in every aspect of quality, quantity, reliability, and speed creating precision metal components with investment casting using any metal.

Furthermore, once you associate with us advanced high-grade manufacturing becomes a part of your daily life, without having the need to look back at quality assurance.

If you are still here, reading this we know what your next step is going to be. But just to be sure and save you a few more of your precious seconds of time.

Click Here to Connect with Our Experts Today!

Considering investment casting, consider the leading investment casting manufacturers- Sumangal Castings Pvt. Ltd.